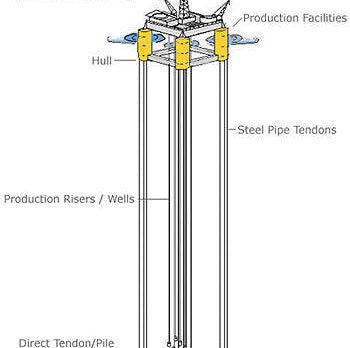

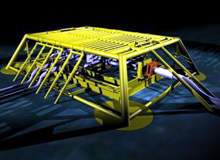

Key applications for the oil-and gas industry include: methanol/ethanol injection, chemical injection packages, H2S and CO2 re-injection, condensate forwarding or re-injection and glycol injection.

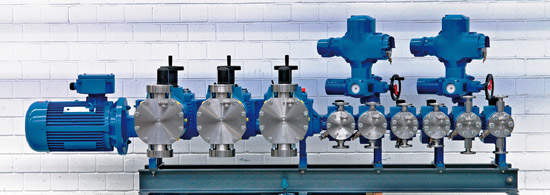

LEWA pumps and systems is the world leader in metering pumps according to API and many other specifications, for plunger, diaphragm, process pumps as well as skids, packages and systems, and provides the widest range of pressures, flow rates and materials covering the toughest applications in the oil and gas industry, on and offshore, up and downstream.

LEWA’s key products include metering pumps, process diaphragm pumps, odorizing systems, solar-, electric motor-, and air/gas driven chemical injection packages, large to small on-/off-shore packages, CO2/H2S re-injection units, custom made high pressure diaphragm pumps and condition monitoring systems for a variety of industries.

These products are supplied to key industries, such as:

- Oil and gas (upstream and downstream)

- Chemicals and petrochemicals

- Pharmaceuticals and personal care

- Foods and beverages

- Plastics processes

- Cleaning and detergents

- Specials (such as gas odorizing)

LEWA’s core expertise includes:

- International project management

- Worldwide on-site presence

- First class service and spare part distribution

- Pre and after-sales services

Full process solution provider

No need to switch to other, non-proven equipment – once the flows and pressures get higher. Over 50 years of sound, practical and proven experience in the oil and gas industry, LEWA can provide the complete range.

Diaphragm metering pumps – LEWA ecoflow

LEWA ecoflow provides the highest reliability. Featuring a wealth of standardised assemblies, LEWA’s ecoflow range of diaphragm metering pumps can be customized for practically every pumping application.

Ecoflow metering pumps incorporate the LEWA Diaphragm Protection System (DPS) that perfectly complements the range’s proven modular design and offers safe control of the diaphragm movement during operation.

In addition to modular, standardised diaphragm metering pumps, LEWA can also deliver specialised solutions to meet the customer’s requirements.

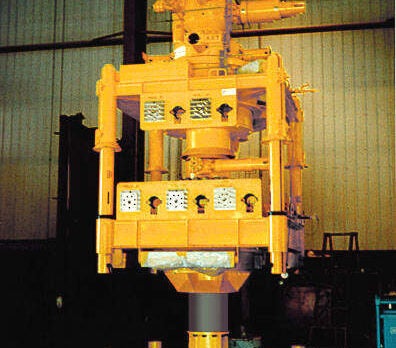

Process diaphragm pumps – LEWA ecoflow and LEWA triplex

LEWA continues to set new standards for process diaphragm pump technology in high-pressure process engineering. With a pressure range of up to 1,200bar, our process diaphragm pumps can quickly and safely transfer critical, toxic and inflammable fluids in a wide variety of operating conditions.

LEWA package engineering

The company delivers engineering and on-site commissioning services for metering and mixing applications, and supplies both proven standard packages and metering packages, tailor-made for specific applications. Competence from one source with a minimum of interfaces and consistent component selection minimizes the risk due to our functional warranty.

LEWA’s metering solutions and odorizing systems are delivered with modern electronics that enable both open and closed loop control and monitoring. LEWA meets all requirements for new systems or upgrades from proportional control up to PLC-operated systems.

LEWA CMS (condition monitoring system)

To ensure continuous operation and avoid costly and time-consuming emergency shut downs, a condition monitoring system, LEWA CMS, offers the most economic solution.

With LEWA CMS, pump life-cycle cost is lowered by reducing machine downtime, accomplished by progressing from preventive to condition-oriented maintenance and further reducing the risk of unexpected pump breakdowns and loss of production.

Best solution and technology for the customer’s benefit

LEWA’s definition of customer benefit includes more than just technical features and high standards for quality. Other important features include our after-sales capabilities, first-class service, a worldwide on-site presence and international project management. Customers are offered competent and comprehensive consulting. The process, the system approach and, in particular, economics are always the focal point.

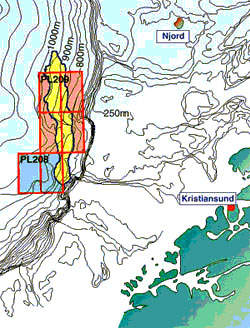

To support our claim of being the market leader, we can name many outstanding and technically extremely demanding applications (environmentally and application-wise).

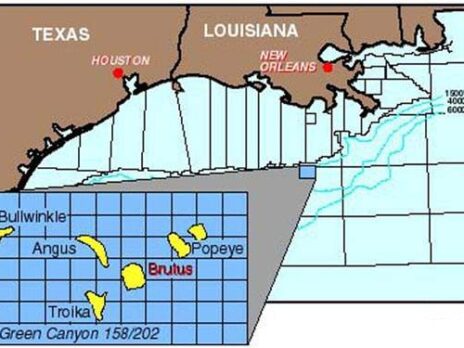

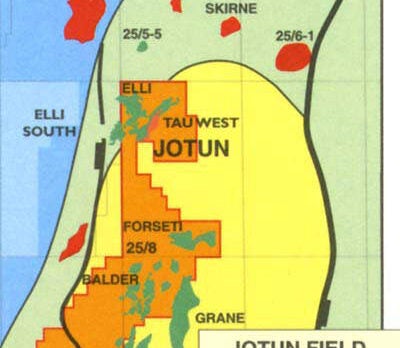

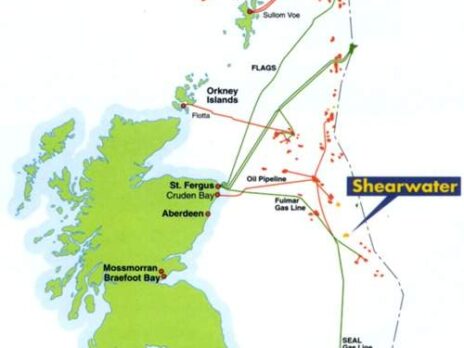

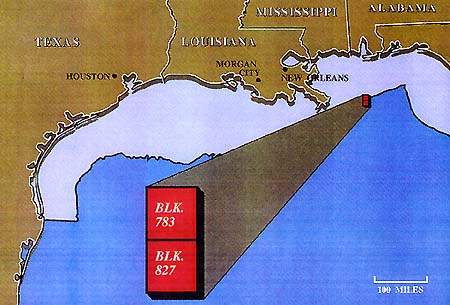

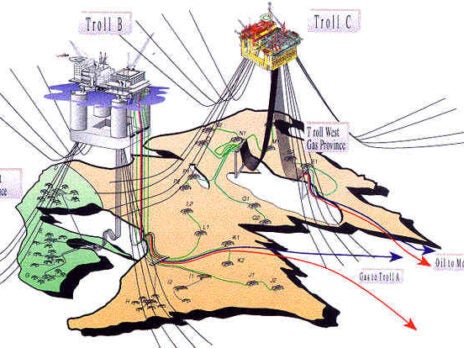

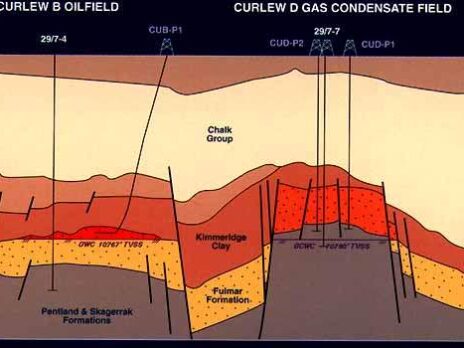

West Africa, South America, the Gulf of Mexico – high-pressure chemical injection (non-lubricating chemicals such as methanol, ethanol). Abrasive catalysts, bentonite – the Middle East, the North Sea, CO2 /H2S reinjection in Canada, and many other locations.